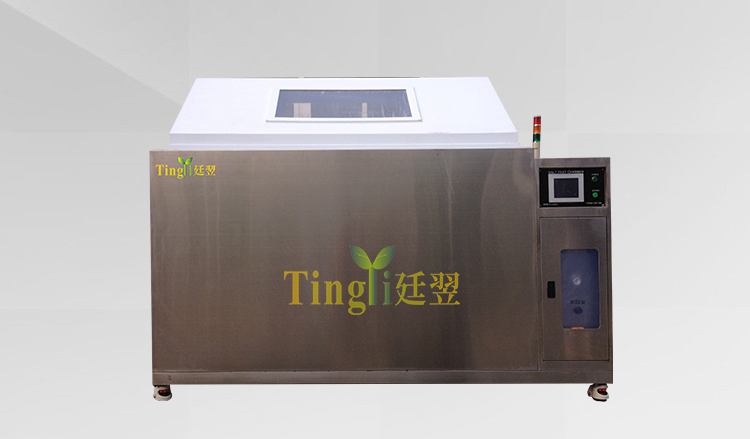

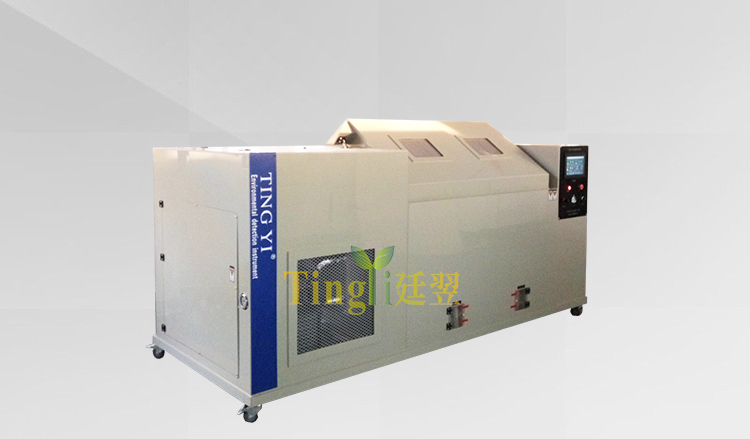

CompoundsaltspraycorrosionTestbox复合式盐雾腐蚀试验箱

Use equipment: through the examination of materials and protective layer of salt spray corrosion ability and similar protective layer of process quality compared and some salt fog corrosion resistance ability evaluation; the product application in parts, electronic components, metal material protective layer and industrial products, salt fog corrosion test.

Main technical parameters of the equipment specification material:

model(L) | Studio sizeD*W*H(mm) | Carton sizeD*W*H(mm) | test method |

TY/YW-90型-270L | 900*600*500 | 1430*780*1280 | (NSS/ACSS): 35℃±1℃,47℃±1℃ (CASS): 50℃±1℃,63℃±1℃ |

TY/YW-120型-600L | 1200*850*500 | 1775*1000*1385 | |

TY/YW-160型-900L | 1600*1000*600 | 1350*1980*1280 | |

TY/YW-200型-1200L | 2000*1000*600 | 1200*2280*1580 | |

temperature range:-20-80℃Evenness degree:≤±2℃,Temperature fluctuation degree:≤±1℃, Humidity range:20-98%R.H Humidity deviation:75%R.H以下±5%;75%R.H以上+2、—3%RH。 | |||

Note: other temperature and humidity of the size of the material can be customized according to requirements, equipment in kind prevail, the experimental data are in 25 DEG C no-load conditions measured | |||

Construction | |||

Test case body | Using PP m yellow / light gray PVC/ shell optional stainless steel plate / glass steel, the thickness of 5 ~ 8mm, durable temperature at 60 C, solid structure | ||

water tank | PP m yellow /PVC gray impact resistant plate, thickness of 5 ~ 8mm | ||

Test chamber cover | Impact resistant transparent acrylic plate, the thickness of 5 to 8mm. Inside and outside the double edge thickening, prevent long-term high temperature distortion | ||

Reagent added bottle | Hide one type of cleaning is easy, easy to operate. | ||

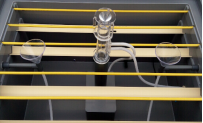

Laboratory basket | PVC /PP gray Beige impact plate, can freely adjust the angle of 15 degrees and 30 degrees test angle | ||

Pressure air drum | Grade a PP/SUS304 stainless steel, high temperature, high pressure, high corrosion resistance | ||

Make-up water system | |||

water supply | Automatic / manual | ||

drainage | Automatic / manual | ||

Yi Ting instrument humidification system | |||

humidification | Stainless steel humidification pipe into the studio in the studio of the fan for uniform mixing, humidity using the wet and dry bulb temperature. | ||

Thermal system | |||

heating | Adopt the direct heating method, the heating speed is fast to reduce the standby time, when the temperature reaches, the automatic switching constant temperature state, the temperature is accurate, the power consumption is little. Pure titanium heating pipe, acid and alkali corrosion, long service life. | ||

supply gas | |||

Air compressor | Customer owned | ||

Pressure regulating valve | 0.2-0.4Mpa/0.07-0.17Mpa | ||

Yi Ting instrument control system | |||

Control system | LCD type double digital display temperature controller with microcomputer automatic calculation function, the control error of plus or minus 1 DEG C. Laboratory heating tank with liquid expansion safety temperature controller 0~120. C programmable time controller 0.1S~99h LCD digital display (optional touch screen, TEMI series intelligent instrument) | ||

sensor | Pt100 | ||

Test time | (S、M、H) | ||

Electrical components | |||

components | Selection of LG/ / CHINT / Schneider / West Germany and other well-known brands, stable performance, long durability | ||

Spraying Systems | |||

Spray mode | Continuous / intermittent spray, high efficiency and intelligence | ||

Spray amount | 1~2mL/80cm²/1h | ||

Mist | Remove salt spray, prevent corrosion of gas flow out of the laboratory and other precision instruments. | ||

| |||

compressor | Century French "Taikang" full closed refrigeration compressor unit, each unit were after the European Computer Networking itemized monitoring and security code, through the Internet search | ||

Refrigeration accessories | Solenoid valve: Japan Heron works; filters: (USA) Emerson; voltage controlled / thermal expansion valve: (Denmark) / (Italy) Castel properly | ||

Refrigerant | R404A、R23 | ||

Cooling mode | Air cooling | ||

other | |||

Safety protection system | Over temperature alarm, leakage protection, under phase lack phase protection, over current protection, fast fuse device, a compressor high and low voltage protection, compressor overheat protection, compressor over current protection, line fuses and sheath full type terminal, water protection, to protect | ||

Power Supply | AC220V~AC380V±10%50Hz±0.5Hz | ||

Meet the standard | GB/T2423.17-2008 salt spray test method GB/T10125-1997 corrosion tests in artificial atmospheres _ salt fog test Technical conditions of GB/T10587-2006 salt spray test box Determination of heat resistance, salt fog resistance, weather resistance GB/T1765-1979 (Accelerated) film system test GB/T1771-2007 paints and varnish - Determination of resistance to neutral salt spray GB/T12967.3-2008 aluminum and aluminum alloy anodic oxide film detection method third parts: Copper acceleration GB/T5170.8-2008 as well as the equivalent of IEC, MIL, DIN, ASTM and other related standards GB/2423.1-2008 (IEC68-2-1 cold) test A: low temperature test GB/2423.2-2008 (IEC68-2-2 dry heat) test B: high temperature test | ||

(model appearance of technical information are subject to change without notice, Ting Yi has the power of final interpretation)

Ting Yi xenon test box configuration strong high price | |||

|  |  | |

A standard key type microcomputer controller. Not only, more high performance touch screen controller Powerful functions, easy to use, interface pretty outrageous | Using the computer technology, the advanced PID control method to measure and control the temperature and humidity of the environment, and can be used with constant temperature and humidity equipment. For salt fog test box, alternating high and low temperature test box, constant temperature and humidity test chamber, dust rain xenon lamp UV ozone. Can display and control interface is clear and intuitive touch, select menu, easy to use, stable and reliable performance. The control program is flexible, cost-effective. | ||

1 true color touch screen 4.3 inch /5.7 inch and 7 inch /10 inch 2 two control methods: program / value, program can edit 120 sets of programs, the largest programmable 100 segment group, all cycle, circular section; 3 sensor types: two PT100 input (optional electronic sensor input) 4 alarm: alarm 16 DI external obstacles; 5 temperature measuring range: -90.00 DEG --200.00 DEG C, + 0.2 error; 6 humidity measurement range: 1.0%--100%RH, error 1%RH; 7 communication interface (RS232/RS485, the longest distance of 1.2km[optical fiber communication up to 30km]); 8 interface language: Chinese / English; 9 Chinese character input function, edit input manufacturers information, fault name, test name, etc., display intuitive, clear; 10 curves: real time temperature, humidity PV, SP curve; 11 with network function IP address can be set; can take the printer (USB function optional); 12 products show clear intuitive three-dimensional sense of strong, programmable control system is flexible and convenient operation, stable performance, work more efficient, flexible installation, can be embedded or embedded installation; | |||

|

|

| |

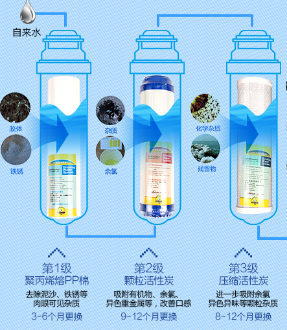

Two. New, CommScope granular activated carbon filter, water filter and even drinkable Perfect solution part of the use of pure distilled water, and lead to poor water quality due to the problem of poor water | |||

|  |  | |

Three. / Schneider / CHINT and other well-known Delixi electrical components Performance is stable and unparalleled, long and durable to prevent the problem of circuit | |||

|  |  | |

Four. Spray systems like art and high-tech combination From saline and atomization, atomization degree, without blocking crystallization, can ensure the test of continuous. The nozzle is made of toughened glass, can adjust the spray volume and ejection angle. The conical diffuser can adjust the spray size, and can make the fog fog off average, nozzle for precision glass nozzle material PYREX nozzle. More domestic first South Korean import nozzle, instead of the traditional glass spray tower. Spray evenly and quickly. | |||

|  |  | |

Five. Pure imported compressor unit fast and efficient energy saving | |||

|  | ||

Six. Europe and the United States refrigeration accessories excellent results The Danfoss, evaporating pressure regulating valve to make the evaporation pressure of the system is kept constant, the surface of the evaporator temperature could be controlled by regulators in the suction pipe on the throttle, so as to avoid long time of low temperature and high humidity or temperature and humidity test evaporator icing test abnormal phenomenon caused by the. The Japanese Heron works two solenoid valves, valve coil battery shell protection class up to IP67. The Emerson Shuangliu thermal expansion valve closure, the expansion valve through the end of the evaporator superheat change to adjust the flow, prevent the emergence of evaporator using area and the compressor cylinder knocking phenomenon. ALCO two pass filter. | |||

Seven. Safety and rest assured that a variety of protection systems do not have to worry about hidden dangers With over temperature alarm, leakage protection, phase lack phase protection, over current protection, fast fuse device, a compressor high and low voltage protection, compressor overheat protection, compressor over current protection, line fuse and the sheath type terminal, water protection, grounding protection. | |||

AC220/380V, three-phase four wire + ground protection; In the frequency range: 50Hz + 0.5 Hz Protection, earthing resistance is less than 4 TN-S or TT power supply; power supply mode, The protective grounding wire, used alone, not with other equipment grounding sharing. |

5, the use of ambient temperature to 35 DEG C Best, use temperature: 15 to 25 DEG C, relative humidity: atmospheric pressure: 86-106Kpa = 85%RH |

In ground level, good ventilation, no flammable, explosive and corrosive gases and dust No strong airflow, around when the surrounding air need forced flow, air flow should not blow directly into the box No, no electromagnetic field near direct sunlight and other thermal radiation source In the peripheral equipment have adequate maintenance space |

1, site drainage: test box near the best can have faucet and floor drain 2, the position of the machine placed behind the wall about 50cm left and right sides of the maintenance of the space. 3, the machine outside for the total power line 2.5mm power line before, please re installing a no fuse switch or gate knife switch (about ky16-25a). 4, the drainage pipe can be used PVC1/2 "hard pipe emissions, should pay attention to the water pipe should be down. 5, the exhaust pipe with hard tube PVC21/2 "hard tube, along the stretch to outdoor emissions, must pay attention to the installation of the exhaust pipe, the machine can be parallel to the down. 6, the installation position of the machine, please avoid direct sunlight, so as not to affect the conditions of the test. 7, the installation location of the machine, should try not to close to other electrical equipment, precision instruments or flammable items, so as to avoid danger. 8, the machine do not force the collision, so as not to rupture, the use of temperature do not exceed the scope of the test standard, so as to avoid deformation due to overheating. |

Maintenance considerations and methods:

Fault indication

A. overtemperature indicator: about two to have over temperature indicator (left for the test room, the right side is saturated barrels). When the temperature Dengliang, have the following three conditions.

1 safety temperature controller alarm device setting error

2 check the temperature setting is too low, please re set

3 if the over temperature indicator light continues to shine, inform us to deal with.

B. low water level indicator: when the light is on, it will cut off the power supply, and then automatically add water until the low water level is put out in the test room or in the saturated barrel.

C. end of the indicator light: this light is lit, indicating the end of the test time.

Two. Judgment and treatment of abnormal function

status | reason | handle |

The laboratory could not rise to the set temperature. | Temperature test chamber temperature controller is set too low Laboratory safety protection switch is set too low Heating system fault Fault relay Controller failure | The temperature controller is set to the desired temperature The safety switch is set to the desired temperature We notice We notice Inform us |

Saturation barrel temperature can not rise to the set temperature | Saturation barrel temperature controller is too low Saturation barrel safety protection switch is set too low Heating system failure Electromagnetic relay fault Controller failure | The temperature controller is set to the desired temperature. The safety protection switch is set to the required temperature. Inform us Inform us Inform us |

Inadequate spray | Spray regulator is placed too low Glass filter blocking in pre heating tank Pressure setting is too low | Adjust the spray regulator Clean the glass filter The pressure regulating valve to 1kg/cm2 air compressor, a pressure regulating valve. The pressure adjusted to 2kg/cm2 |

A device for the air pipe and the water suction pipe of the PS: spray nozzle can not be sprayed (- - suction pipe, L - type air pipe) | 1 air compressor is not running 2 the total open air compressor outlet Closed not open 3 solenoid valve failure 4 pressure gauge failure or pressure is too low 5 electromagnetic contactor fault 6 nozzle block | 1, the key to open the air compressor 2, the air compressor switch 3, we notice 4, we notice 5, we notice 6, remove the nozzle cleaning (please be careful to disassemble and assemble) |

When the water level is less than the warning light | That the water level is too low | Check whether the entry of water source into the water source |

Have normal spray and air compressor is not running. | The air compressor itself has the function of self preservation | Use as usual

|

After the power is turned on | When the water level in the heating water tank is too low, the power supply of the operation will be cut off. | The water level of the heating water tank is added to the normal condition. |

When the temperature controller shows EEE | 1 temperature controller failure 2 sense fault | notification handlers |

When the spray amount is too high | 1 spray regulator placed too high 2 glass nozzle has been used for a long time, and the nozzle diameter is too large. | 1 spray regulator down 2 replace the new glass nozzle |

Maintenance item

1 during the test, if more than 1 months, please replace the water in the heating tank.

2 salt solution is not used for more than a week, please do not use, so as not to affect the quality of the test.

3 if the test time interval is longer than the next, please clean the laboratory after the completion of the test,

And discharge the water in the heating water tank.

The heating water tank of water discharge - open drain valve.

The isolation tank water discharge - the intermediate silicone plug pull up.

The preheating tank in water discharge - internal silicone plug pull up.

In order to ensure the quality of the test, please replace the glass nozzle regularly within 2000 hours.

Refrigeration system maintenance

1 cooling units of the radiator (condenser) should be regular maintenance, keep clean. Dust sticky condenser will make the high-pressure compressor switch jump off and produce false alarms, the condenser should be monthly maintenance, condenser cooling network on chip attachment of the dust suction or boot using hard the hair brush or with high pressure gas mouth blown clean of dust with a vacuum cleaner.

The 2 door or take the test from the furnace, not let the goods on the door to prevent the contact edge glue, glue edge damage and shorten the life.

3 around the body and at the bottom of the ground should be kept clean, so as to avoid a large number of dust suction unit to produce an accident and reduce performance.

Please notice the factory or direct handling of 4. Refrigeration system is the core of this machine, please a year inspection of all brass of any leakage of snow, the horn joint, welding mouth, such as the leakage of grease.

5. Distribution disc large current contact, power distribution room of every year at least clean maintenance more than once, the loose contact will make the equipment in hazardous work state, light burned out component, fire, alarm, personal injury is very dangerous. When cleaning cleaning use a vacuum cleaner to indoor dust suction can be.

6. The humidifier and water disc regular cleaning, so as not to produce scale, effect of vapour emission, a general finish cleaning a test, the scale has been excluded in a timely manner favorable humidifying tube life and ensure smooth flow cleaning when using copper brush wash rinse clean.

. dry and wet ball of yarn sets of frequently check, after test cloth surface is not clean or harden, or in finishing temperature control, continue to do temperature and humidity control of the ball must be replaced yarn test set, or in more than 85 DEG C high temperature control, go on to the temperature and humidity control. The examination such as non absorbent, please replace the, related to humidity testing accuracy and testing yarn set general March a replacement, replacement application cleaning cloth wiping microthermometry, replacement of new test yarn set should first wash the tank clean

8 the examination and adjustment of the water level of the wet bulb

The water level of the water drum can not be too high, too high to cause the water to overflow the water drum or too low to cause the wet ball to test the yarn sleeve, which affects the accuracy of the wet ball. The water level is about six minutes. The water level of the water barrel is adjusted, and the height of the water box can be adjusted.

9. The distribution box two over temperature protection device setting value, please do not just debugging, factory tuned, the protective switch is protection of heating pipe and a humidification tube air burning and water shortage alarm. Set point = temperature set point + 20 DEG to 30 DEG C, temperature test box rose to super thermostat set point, heater power supply is stopped, the overheat] over temperature warning lights but the fan is running, if long time operation and supervision, running before do not have to check over temperature protection device is properly set up.

10 inspection and maintenance of waterways

Water pipe is easy to block leakage device, please be sure to check there is no leakage plugging water phenomenon, please promptly eliminate or inform us if there is. In the humidifier water storage monthly replacement to ensure clean water, the water flow is smooth.

11 condenser dust removal

The condenser should be maintained at regular intervals, using the vacuum cleaner to remove the dust from the condenser heat sink or the use of high pressure air.

12 when the test product time to get the product, must be in the shutdown state and the staff must wear a good dry, electricity, temperature resistant gloves to take place the product.

External cleaning and maintenance machine in 13 cases should be removed before operation.

The power distribution room is cleaned at least once or more every year, and can be used for cleaning the indoor dust. The exterior of the box must be cleaned more than once per year, which can be cleaned with soap and water.