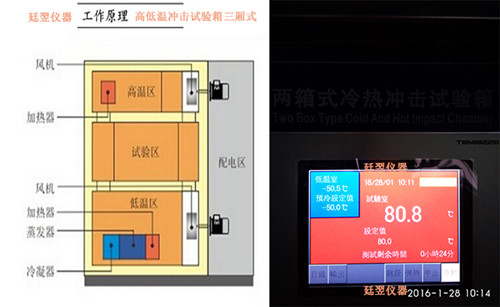

高低温冲击试验箱、冷热冲击试验箱(三厢)Highandlowtemperatureimpacttestcase

Use equipment: thermal shock test chamber is industry of metal, plastic, rubber, electronics and other materials necessary test equipment to test the structure of the material or composite material, in an instant by a very high temperature and low temperature continuous environment bear the degree, can in the shortest time test sample due to thermal expansion and contraction caused by the changes of chemical or physical damage.

Main technical parameters of the equipment specification material:

| model(L) | StudiosizeD*W*H(mm) | CartonsizeD*W*H(mm) | powerKW | temperature | Test piece | |

| TY/LRCJ-50L | 350*400*350 | 1900*1300*1750 | 14 | -60℃~200℃ Impact range -40℃~130℃ -55℃~150℃ | ≤7kg | |

| TY/LRCJ-100L | 400*500*500 | 200*1400*1900 | 16 | ≤10kg | ||

| TY/LRCJ-250L | 600*700*600 | 2200*1100*1950 | 20 | ≤20kg | ||

| TY/LRCJ-500L | 800*800*800 | 2400*1700*2300 | 25 | ≤50kg | ||

| Fluctuation degree | ±0.5℃ | |||||

| Evenness degree | ≤±2℃ | |||||

| recovery time | ≤5min(And temperature recovery conditions, cooling water temperature, exposure temperature difference, the constant temperature time, the weight of the sample | |||||

| Conversion time | From the low temperature zone to the high temperature zone / from the high temperature zone to the low temperature zone≤15S | |||||

| heating rate | +60℃~+200℃≤30min | |||||

| cooling rate | -25~-60℃≤60min | |||||

| Test methods | Test sample static three compartment impact mode | |||||

| Note: other temperature size of the material can be customized according to requirements, equipment in kind prevail, the experimental data are in 25 DEG C no-load conditions measured | ||||||

| Construction | ||||||

| Internal material | High quality, high grade, thickened, 304SUS, stainless steel plate | |||||

| External material | Thickened high quality cold-rolled steel electrostatic spraying, strong, beautiful, durable, durable | |||||

| material | Superfine glass wool / or rigid polyurethane foam material, excellent low temperature insulation performance | |||||

| heater | Stainless steel heater | |||||

| Circulating fan | Centrifugal fan | |||||

| Basket frame | Stainless steel basket 2 | |||||

| Yi Ting control system | ||||||

| Control instrument | South Korea three yuan 2700/TEMI-8226 large screen color touch thin screen program or set the value of the control mode of the two free conversion can be connected to the computer and English switching. High resolution, more accurate and better use | |||||

| sensor | -50 ~ -70 to +150 DEG C for three yuan, South Korea Finland Weisala / PT100 platinum resistance | |||||

| Electrical components | ||||||

| Electrical components | LG/ / CHINT / Schneider / West Germany and other well-known brands, stable performance incomparable, long durability | |||||

| Shanghai Yi Ting instrument refrigeration system | ||||||

| Refrigeration compressor | The imported Bitzer / frascold / "Taikang" full closed refrigeration compressor unit, each unit were after the European Computer Networking itemized monitoring and security code, through the Internet search | |||||

| Attachment | Solenoid valve: Japan Heron works; filters: (USA) Emerson; voltage controlled / thermal expansion valve: (Denmark) / (Italy) Castel properly | |||||

| refrigerant | Environmental protection refrigerant R404A low pressure cycle, R23 high pressure cycle | |||||

| Cooling mode | 风冷/水冷(water tower10ton、15ton、20ton) | |||||

| 其他 | ||||||

| Power Supply | AC380V±10%50Hz±0.5Hz | |||||

| Safety protection system | Over temperature alarm, leakage protection, under phase lack phase protection, over current protection, fast fuse device, a compressor high and low voltage protection, compressor overheat protection, compressor over current protection, line fuses and sheath full type terminal, water protection, to protect | |||||

| Total powerKW | 11/15/18 | |||||

| Meet the standard | GJB150.3 high and low temperature impact test Technical conditions of GBT10592-1989 high and low temperature test chamber GB2423.1-2008 (IEC68-2-1) test A: low temperature test method GB2423.2-2008 (IEC68-2-2) test B: high temperature test method Requirements of readiness and methods of inspection and assessment for SJT31391-1994 test cases | |||||

(model appearance of technical information are subject to change without notice, Ting Yi has the power of final interpretation)

The impact of high and low temperature test box configuration strong high price Ting Yi | |||

|  |  | |

|  |  | |

1. Fast and efficient energy saving of pure imported compressor units | 1. Can choose (Bitzer Germany / Italy Fujitsu HO) semi hermetic refrigeration compressor unit, century French "Taikang" full closed refrigeration compressor unit, each unit were after the European Computer Networking itemized monitoring and security code, through the Internet search. 2. For different box temperature requirements, the selection of different units, Ting Yi instrument to ensure the experimental box of cooling rate and can reach the minimum required temperature, the temperature is lower than - 40 box using bipolar cascade refrigeration unit and cascade refrigeration system, including a high pressure refrigeration cycle and a low pressure refrigeration cycle. 3 connector for the evaporative condenser, the function of the evaporator condenser for the low pressure cycle of the evaporator as a high pressure cycle of the condenser, the temperature is not more than -40 of the temperature as long as the use of a single unit can be. 4 constant temperature and cooling by the battery valve to control the output size of the cold, can save about 30% of energy than the traditional hot and cold balance method, greatly reduce the cost of the user's use. After repeated testing, the data is improved. | ||

|  |  | |

Two. Large screen high performance controller three yuan /TEMI series | This product uses computer technology, advanced PID control method to measure and control the temperature of the environment, and can be used with cold and hot shock test equipment. * display and intuitive control interface clear, touch type selection menu, easy to use, stable and reliable performance. This program brings efficient, flexible control, stable performance, flexible control to the user, high-end products with high performance. | ||

True color touch screen 5.7 inch and 7 inch Two 1 control methods: program / set value, the program can edit 120 sets of programs, the maximum can be compiled for 100 sections, the group of all cycle, the segment cycle; 2 sensor type PT100 (thermocouple can be defined) Two three slot 3 slot control options, manual automatic removal of optional 4 the first stage compressor refrigeration temperature display and alarm display | |||

|  |  | |

Three. / Schneider / CHINT and other well-known Delixi electrical components Performance is stable and unparalleled, long and durable to prevent the problem of circuit | |||

|  | ||

Four. Europe and the United States refrigeration accessories excellent results The Danfoss, evaporating pressure regulating valve to make the evaporation pressure of the system is kept constant, the surface of the evaporator temperature could be controlled by regulators in the suction pipe on the throttle, so as to avoid long time of low temperature and high humidity or temperature and humidity test evaporator icing test abnormal phenomenon caused by the. The Japanese Heron works two solenoid valves, valve coil battery shell protection class up to IP67. The Emerson Shuangliu thermal expansion valve closure, the expansion valve through the end of the evaporator superheat change to adjust the flow, prevent the emergence of evaporator using area and the compressor cylinder knocking phenomenon. ALCO two pass filter. | |||

Five. Safety and rest assured that a variety of protection systems do not have to worry about hidden dangers With over temperature alarm, leakage protection, under phase lack phase protection, over current protection, fast fuse device, a compressor high and low voltage protection, compressor overheat protection, compressor over current protection, line fuse and the sheath type terminal and grounding protection. | |||

○ AC380V three-phase four wire + protection ground wire; ○ Voltage fluctuation range: AC220/380V + 10% ○ Frequency range: 50Hz + 0.5 Hz ○ Ground resistance is less than 4; TN-S mode power supply or TT mode power supply ○ The ground wire is used alone and not shared with other equipment. |

○ The use of ambient temperature 5 to 35 DEG C, the best use temperature: 15 to 25 DEG C, relative humidity: atmospheric pressure: 86-106Kpa = 85%RH |

○ Ground level, well ventilated, non flammable, explosive, corrosive gas and dust. ○ There is no strong airflow around, when the ambient air is forced to flow, the air flow should not be blown directly into the box. ○ No electromagnetic field near, without direct sunlight, other thermal radiation source ○Proper maintenance space is left around the equipment. ○ Ground bearing requirements of more than 600kg/ square meters (the upstairs venue) ○ Venue: drainage test box near the best can have faucet and floor drain |

Maintenance considerations and methods:

The operation of the high and low temperature impact test chamber is divided into five parts: preprocessing, initial detection, test, recovery, and final detection. Yi Ting and share it with the content of process:

1 pretreatment: the test sample is placed in the normal test atmosphere, until the temperature is stable.

2 initial detection: the test samples and standard requirements, in line with the requirements directly into the high and low temperature impact test box.

3 test:

1) the test samples should be in accordance with the standard requirements placed in the test chamber, and the test box (room) temperature rise to a specified point, keep a certain time to test samples to reach stable temperature. For a long time.

2) after the end of the high temperature phase, in 5min test samples of conversion to have been adjusted to 55 DEG C and low temperature test chamber (room), maintain 1 hour or until the test sample to reach steady temperature, for a long time.

3) after the end of the low temperature phase, in 5min test samples of conversion to have been adjusted to 70 DEG C high temperature test box (room), maintain 1 hour or until the test sample to reach steady temperature, for a long time.

4) repeat the above experimental method to complete the three cycle. According to the size of sample size and space, time may be a slight error.

4 recovery: the test samples taken from the test chamber, should be under normal atmospheric conditions to resume, until the test samples to achieve temperature stability.

5 the final test: the extent of the damage in the control standard and other methods to assess the results of the test.

Not test

Explosives, flammable substances, combustible materials, oxides of the nature of the class, flammable materials

1 do not put the test equipment power supply in the power supply, otherwise it will increase the equipment power supply load. Unless the device is left with a sample power interface.

2 test is strictly prohibited flammable, explosive, high corrosion, strong radiation items.

3 equipment under the state or the operation of the power of handling, maintenance.

1, high temperature scald, hot and cold shock test box in the high temperature test case temperature is very high. Test process or the end of the test, such as the need to open the box, open the door to be particularly careful, remember, along the way to walk in the direction of walking, so as not to burn.

2, low temperature frostbite, thermal shock test box in low temperature test box temperature is very low. In the process of test or test is finished, such as the need to open the door to take extra care to avoid frostbite.

3, high temperature scald, hot and cold shock test box in the high temperature test case temperature is very high. In the course of the test or the end of the test, if you need to open the door to be particularly careful, so as not to burn.

4, electric shock, although the device has a sound anti shock measures, but still need to pay attention to, especially the electrical control system, the work of the case, do not touch electrical parts.

Maintenance method

A. cold and heat shock test machine refrigeration unit of the radiator (condenser) should be regularly maintained, keep clean. Dust sticky condenser will make the high-pressure compressor switch jump off and produce false alarms, the condenser should be monthly maintenance, condenser cooling network on chip attachment of the dust suction or boot using hard the hair brush or with high pressure gas mouth blown clean of dust with a vacuum cleaner.

B. open and close the door or take the test from the furnace, not let the goods on the door to prevent the contact edge glue, glue edge damage and shorten the life.

C. around the body and at the bottom of the ground should be kept clean, so as to avoid a large number of dust suction unit to produce an accident and reduce performance.

Please inform us or direct handling D. thermal shock test machine refrigeration system is the core of this machine, please half the inspection of all brass of any leakage of snow, the horn joint, welding mouth, such as the leakage of grease.

E. distribution disc large current contact, power distribution room of every year at least clean maintenance more than once, the loose contact will make the equipment in hazardous work state, light burned out component, fire, alarm, personal injury is very dangerous. When cleaning cleaning using a vacuum cleaner will indoor dust suction can be among.

F. thermal shock test machine power distribution box and two over temperature protection device setting value, please do not just debugging, factory tuned the protection switch is to protect the heating tube air burning and alerts. Set point = temperature set point 20 DEG to 30 DEG C.

H. hot and cold shock test machine when the test product time to take products, must be in the shutdown state and the staff must wear a good drying, electricity, temperature resistant gloves to take and put products.

Internal and external cleaning and maintenance of I. cold and heat shock test case.

J. thermal shock test machine before the operation should be internal impurities (material) clearance.

The K. distribution room is cleaned at least once or more every year, and can be used for cleaning the indoor dust. The exterior of the box must be cleaned more than once per year, which can be cleaned with soap and water.

choose

Desire to buy a product, need to have a general understanding of the product, what is hot and cold impact test box?? a Shanghai court tomorrow equipment plant hot and cold impact test box by cool storage, tested the products stationary of hot and cold alternately impact, testing products in rapid temperature changes after the performance and parameters. That is to say, it is used to test composite materials and structural materials, at the moment, and high temperature and low temperature by the continuous environment can bear degree, that is to say, in the shortest time to test its due to thermal expansion and contraction caused by the changes of chemical or physical damage. The applicable objects including metal, plastic, rubber, and other electronic materials.

Thermal shock test box purchase should pay attention to five aspects: temperature shock, test load, return time, in addition to the frost time, sensors placed.

When purchased, they have their own requirements, the impact of the temperature is to refer to the actual test area can run to the maximum range of temperature. Attention is not the limit temperature of preheat and pre cooling chamber; the direct effect of test load can be placed on the number of test products. Generally speaking, the bigger the weight is, the better it is, the time it takes to switch from one point to the other. Our common specification agreed to less than 5min. The smaller the time the better; the longer the cream, the longer the better. Now the next Ting can do 1000 cycle defrosting time is very ideal. Defrost interval is short that air tightness of the device is worse; the sensor must be positioned within the test area. If placed in the duct interior, and although the test area only 10cm distance, but this energy difference is quite large. Temperature change test and could not reflect the product surface.